102-9-a

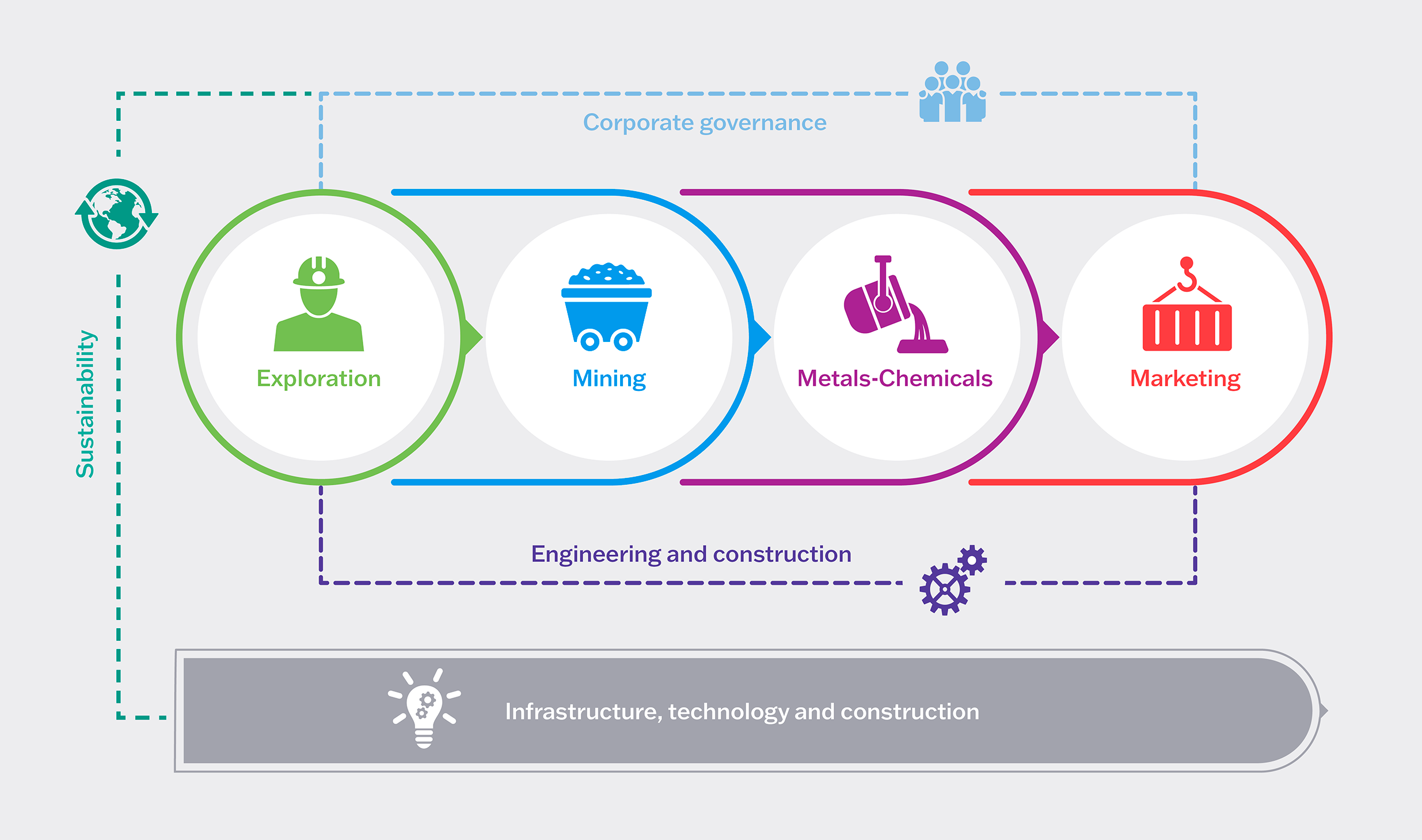

Through efficient operation of our value chain, we maintain our leadership position in the industries where we operate.

102-10, 102-48, 102-49

During the year, the global pandemic caused a crisis the world was not prepared for, and the sudden change in lifestyles necessary to contain the contagion set off a deep economic recession.

With the decisive support of the chairman of our Board of Directors, the Mexican Mining Chamber and other companies in our industry, as well as the mining union FRENTE and other business chambers and organizations, we engaged in constant dialogue with federal, state and municipal authorities to have the mining industry classified as an essential economic activity, in order to maintain limited operations, while placing a priority on the health of our employees and surrounding communities at all times. Thanks to these efforts, the mining-metallurgy industry was declared an essential activity in late May, aligning Mexico with countries like the United States and Canada.

PEÑOLES VALUE CHAIN

We immediately set in motion an emergency plan to mitigate the impact of the public health emergency, with a priority on protecting personal health and safety as well as jobs. In the months of June, July and August we began a process of safe return to work with staggered hours for our personnel, guaranteeing all preventive measures established by the Ministry of Health, the Ministry of Labor and Social Planning, and internal protocols.

With field exploration work suspended for seven months, our efforts focused on studying and analyzing the information collected, and on investigating new prospective areas.

In the Mines Division, the startup of the new Capela polymetallic unit in Guerrero was delayed due to sanitary restrictions that limited the number of personnel onsite and a lack of support from suppliers in the final delivery and commissioning of the main equipment. Although production was not as high as expected, at the end of the year the plant had reached 99% of its milling capacity and succeeded in producing concentrates with zinc content of 53% on average, and recoveries within the expected range.

STRENGTHENED BY

the efficiency of our operations.

99%

milling capacity and 53% concentrates with zinc content, on average, at Capela, in spite of closed operations.

We devised an emergency plan to mitigate the impacts of the pandemic, prioritizing our people’s health and safety as well as their jobs.

Aerial view of Capela at sunset

In April, we announced the difficult decision to suspend operations indefinitely at the Madero zinc mine in Zacatecas, and the Milpillas unit in Sonora, which produces copper cathode, because of the steep drop in the price of these metals. High operating costs and low grades meant that, for the moment, these operations were no longer profitable. For now, Milpillas will continue turning out copper cathode using the ore deposited at the leaching pads. As a result of this suspension, 267 employees were relocated to other company operations and the remaining 630 were laid off with severance pay according to the law and the respective union contracts. Also, and as planned, the Bismark zinc mining unit concluded its life cycle after 28 years of operations, having exhausted its reserves.

In metallurgical operations, refined gold production was 14.0% lower than the previous year, mainly due to lower treatment of doré at Herradura and Noche Buena. Some remitters temporarily suspended their supply of concentrates, and although the situation normalized toward mid-year, we had some difficulty in supplying the lead smelter with the proper amount and quality of mixtures for processing. With this, silver and lead production declined 2.4% and 6.2%, respectively.

104.7%

of our electricity needswere generated by our own power generating plants, including Eólica Mesa La Paz.

Mesa La Paz wind farm

In the zinc refinery, where capacity was expanded to 350,000 metric tons a year of production a couple of years ago, most of the technical problems have been solved relating to balancing the processes and ensuring the correct interaction of the old (roasting) plant and the new direct leaching plant. This, combined with a lower volume of concentrates treated due to the contingency, caused an 8.0% reduction in refined zinc output, to 260,943 metric tons. We are confident that with the adjustments made, the zinc refinery will be working at capacity in 2021.

Another challenge we faced was a temporary contraction in domestic refined zinc demand, although we were able to place our products on export markets.

Demand also fell sharply for chemical magnesium byproducts, mainly refractory and caustic grade. Sodium sulfate volume totaled 745,892 metric tons, 3.7% less than the year before, but magnesium sulfate broke a production record with 62,583 metric tons due to strong performance in the domestic agriculture industry.

On the matter of energy, our priority was to ensure a supply for our operations at competitive costs. Our portfolio of power generating plants produced enough to supply 104.7% of our own needs, including the power from the Mesa La Paz wind farm, which began supplying energy in April. However, we had to buy more energy from the Federal Electricity Commission, with a 14.0% higher cost, due to delays in the entry into force of new transmission agreements and migration of qualified users to the wholesale electrical market, which were the result of the energy policy decreed by the Mexican authorities. We remain committed to increasing the proportion of clean energy in our mix, and hope the change in the country’s energy policy will allow us to do so.

Leaching pads at Milpillas

Leaching pads at Milpillas